RETARDER /PROOFER

Model: DC-236SG

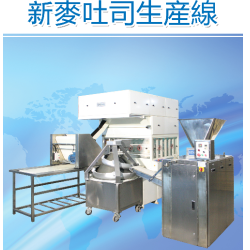

Category: Bakery Machinery & Equipment

Exhibitor: SINMAG EQUIPMENT CORPORATION

Booth No: J518

Characteristic

Four-band freeze-drying proofing panel operation steps:

Assume that the dough is scheduled to be placed at 18:00.

Set the proofing box to start 30 minutes earlier with a temperature of -10°C and a humidity of 85% RH.

When the temperature inside the proofing box reaches the set temperature, place the dough.

Step 1: The freezing time is set to 18:00, and the temperature is set to -10°C.

Step 2: The refrigeration time is set to 20:30, and the temperature is 3°C.

Step 3: The first proofing time is set to 4:30, and the temperature is 12°C.

Step 4: The second proofing time is set to 6:00, and the temperature is 26°C.

Starting at 7 o'clock, the dough has completed fermentation and can be baked.

The above times are for reference only. Customers need to adjust them according to their own operation requirements and time.

Operation steps for the two-band frozen storage and fermentation panel:

Assume that the dough is scheduled to be placed at 17:00.

Set the fermentation box to start 30 minutes earlier with a temperature of 3°C and a humidity of 85% RH.

When the temperature inside the fermentation box reaches the set value, place the dough in it.

Step 1: The refrigeration time is set to 17:00, and the temperature is set to 3°C.

Step 2: The fermentation time is set to 4:00, and the temperature is set to 26°C.

Starting at 7 o'clock, the dough has completed fermentation and can be baked.

The above times are for reference only. Customers can adjust them according to their own working hours.

Other Products

Products you may be interested in

Highest Rated Products